Technology and equipment for making wet feed mixtures

Technology for preparing wet feed mixtures made from soybeans, peas, wheat, maize and other leguminous plants

To be considered by managers, zootechnicians and cattle farm engineers.

The method of feeding animals with dry combined feeds developed in the 1980s though it presupposes extended storage and minimum manual labor has caused lung silicosis, stomach problems, etc. in many animals. Exposed to severe thermal processing, dry feeds preserve just a small part of natural substances and compounds that are present in raw stuff. Besides, dry feeds cost much more than the initial raw stuff.

Besides, as most cattle farms grow soybeans, peas, wheat, etc. and technologies for preparing feeds including steaming, mixing and crushing raw stuff are well-known to them, it is evident that wet feed mixtures should be made on the farm. But as distinct from old-time methods, present-day technology must be less labor- and energy-consuming.

As an example of wet feed preparation let us consider processing soybeans which constitute the protein basis of any combined feed.

A soybean is known to be a mine of essential amino acids, polyunsaturated fatty acids, poly- and monosaccharides, B, C, D vitamin groups, numerous microelements. But at the same time raw soybean contains a number of harmful substances (tripsin inhibitor, urease, other enzymes), which necessitates thermal processing. But this together with soaking makes soybean processing much more expensive than the processing of wheat.

Much less expensive and having a longer storage period is the soy product obtained with the help of an extruder, this is a device which uses high pressure and high temperature. But soy cake obtained is of very low quality as soy loses most vitamins and fats (unique linolenic and linoleic acids), etc. Besides, such antinutrients as tripsin inhibitor are not inactivated to a safe level.

Nowadays very popular in Ukraine became so called "soy cows", that is, machines that crush and boil soy by means of steam.

The finished product - soy milk - is of high quality but the problem is that such machines employ steam generators which consume a lot of energy. Besides, "soy cows" produce 30% sediment (fiber, cellulose, etc.), which hampers feed even distribution.

Moreover, soy milk nutritive value is greatly affected by repeatedly soaking and washing beans, which causes water-soluble protein, starch and sugar washing out. Furthermore, under these technologies bean skins are removed, which adds to useful stuff loss. And to crown it all, the waste waters are to be treated to avoid environment pollution, thus production cost is additionally increased.

As a result, soy milk obtained under conventional technologies cannot reduce sufficiently the cost of young cattle and pigs fattening.

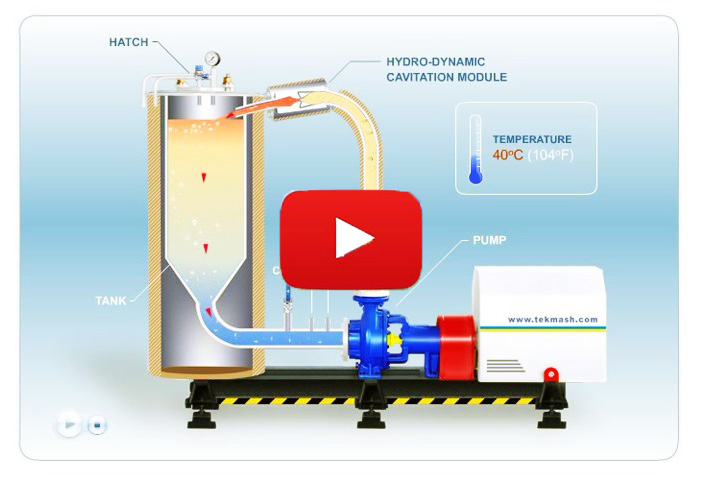

Devoid of these shortcomings is the innovative TEKMASH hydrodynamic technology for making 28% soy paste which can be later watered to milk consistence. Under our technology soybeans are not to be preliminarily ground as grinding, thermal processing and homogenization are going on simultaneously in TEK-SM unit due to hydrodynamics. We do not use steam and heat exchangers, thus making our equipment highly efficient and energy-saving. For example, you will need only 0.25 kWh to make 5-6 l of 7-10% vegetable milk.

According to TEKMASH technology, soybeans are soaked only once, besides, the water used for soaking goes to the unit bunker and all water-soluble substances in this water get into the paste. Besides, our technology does not presuppose hulling, all this making it wasteless and ecologically friendly.

Being anaerobic, TEKMASH technology fully preserves the whole set of vitamins, minerals, essential amino acids, fatty acids, starch and sugar, which distinguishes it from soy meal or cake production methods conducive to useful substances loss.

Soya milk made according to TEKMASH technology costs 2-4 times less than that produced by "soy cows", its nutritive value being much higher. Owing to this, cattle farms can save up to 15% cost when fattening 6-month old calves.

Soybean processing technology using TEK-SM unit makes it possible:

- to preserve all useful substances in soybeans due to unique processing technology;

- to reduce soy milk cost:

- almost 4 times as compared to milk from soy meal;

- 1.7-2.2 times as compared to milk produced conventionally with the help of steam;

- to increase farm profitability by 15-20% due to higher gains and lower feed cost;

- to reduce 3-5 times energy inputs for making liquid feeds;

- to supplement feed mixture with necessary minerals, biologically active and pharmaceutical substances in the course of its making;

- to prevent carcinogens formation caused by thermo-oxidative degradation when the product is scorched on convective surfaces in conventional equipment

- to save money due to absence of costly treatment facilities.

TEK-SM hydrodynamic units are ideal for making liquid and paste-like feed mixtures on the basis of soybeans, peas, wheat, barley and other leguminous plants.

Conventional feed manufacturing methods

| Basic operations | ||

| Crushing | Water-thermal processing | Mixing |

| Mechanical crushing of feed components to obtain particles suiting animals | Bacteria, fungi, insects destruction. Splitting indigestible structures. Moistening feed particles to prevent their swelling in stomach. |

Preparation of homogenous feed mixture from different components, supplements and medications. |

| Equipment to be used | ||

| Crusher | Steaming mixer | |

| Crusher Extruder Granulator |

Mixer | |

An illustrative example of TEK-SM unit ap

Kirovograd Research Institute experimental farm bought TEK-2SM low-powered unit to make 300 l vegetable milk an hour for feeding calves. Several months later on gaining necessary experience they bought TEK-4SM unit to make 1000 l/h, as economic benefits were evident.

Due to TEKMASH® technology introduction in 2008 the farm yielded the following results:

- cow milk savings amounted to 91.8 t as a result of using soy milk to feed 340 calves

- profit out of additionally sold milk amounted to 215 700 grivnas

- net profit out of using soy milk amounted to 113 500 grivnas, soy milk production cost being 102 200 grivnas.

On the whole, soy milk feeding increased daily weight gains by 5%, whereas beef production profitability increased by 10.8% (from 7.1% to 17.9%).

TEK units use in animal husbandry

Field of application:

- Preparation of paste-like feed mixtures from soybeans, peas, wheat, barley and other leguminous plants.

- Preparation of soy (pea) milk.

- Heating water and disinfectant solutions.

- Pasteurization of cow milk for feeding pigs and dairy calves.

- Milk pasteurization.

ILLUSTRATIVE VIDEO:

Application on the farm

Equipment operating principle

- TEK-PD cavitation-type dispersing pump

SIPE TEKMASH Institute offers dispersing pumps for making fine-dispersed food emulsions and suspensions, 10-25 m³/h capacity.

More... - Feedstock feeding equipment. Milk substitute.

The site contains information on fattening animals, on soy paste properties and soybean processing technology (animal feeding).

More... - Condensed milk line TEK-CML

Condensed milk production line

More...

- IndiaSASIL AGRO LLP

'Kshiti', 127/2, Rockel Lane,

Vakhar Bhag,

Sangli - 416416

MAHARASHTRA, India

Shreyans Shah

tel. +91-9011068877

e-mail: sasilexim@gmail.com - Colombia & LA

KAVITEC S.A.S.

Carrera 16 # 9-68

Dosquebradas, Risaralda, Colombia.?ngela Mar?a Sanz E

Gerente Comercial

email:

angela.sanz@kavitec.co

Tel?fono: 3306102

Cel: 3043289012 - Ukraine