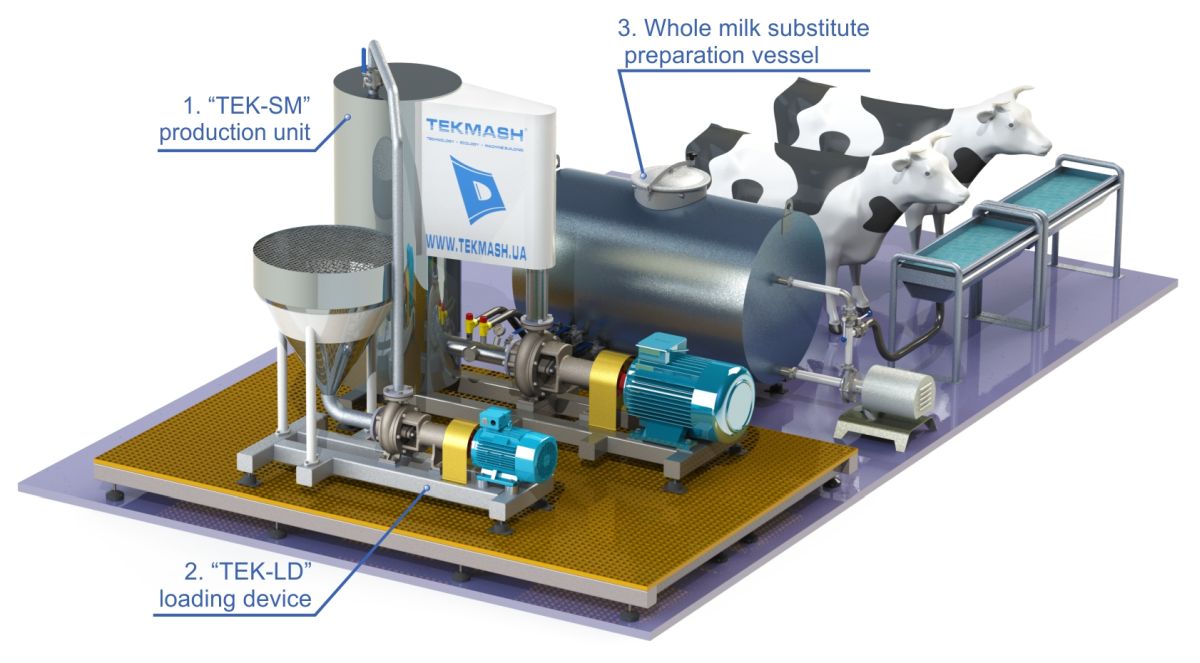

Production line for making wet feed mixtures

Production line for making wet feed mixtures (WFM) used in animal husbandry

![]() Production line for making wet feed mixtures »

Production line for making wet feed mixtures »

“TEKMASH®” technology provides fine grinding, mixing and thermal processing of mixtures by means of hydrodynamics (science dealing with liquid movement) with no heating elements used. It permits making 5-6 l vegetable milk using not more than 0.25 kWh electric energy.

While dry feed assimilation does not exceed 55-60%, “TEKMASH®” feed mixtures are 65-85% assimilated. The equipment is repaid within 6 months time, which makes the livestock industry not subsidized but profitable.

Concentrated sterile paste-like supplements (based mainly on peas, soybeans, lupine) are produced using TEKMASH® technology which preserves all vitamins and minerals, as opposed to cake or soya meal which contain much less useful substances.

The safe level of tripsin inhibitor (up to zero level) is guaranteed.

TEKMASH® technology enables:

- to increase 2-4-month old pigs daily gains by 10-15% (for example, from 450 g to 520 g) due to supplying their ration with 1-2 l vegetable milk;

- to increase cows milk yields by 1-3 l due to supplying their ration with 3-4 l vegetable milk;

- to save up to $25-40 on each 6-month old calf when using vegetable milk (mainly soy milk) instead of skim milk or whole milk substitutes (WMS);

- to increase fattening bull-calves daily gains by 150 – 200 g due to supplying their ration with 3-4 l of 10% vegetable milk;

- to increase farm profitability two or more times due to higher weight gains and reduced feed cost;

- to cut energy consumption 3-5 times while making wet feeds as compared to conventional technologies;

- to introduce necessary mineral, biologically active and pharmaceutical substances while making feeds.

PRODUCTION LINE COMPOSITION:

1. TEK-SM PRODUCTION UNIT

The unit consists of a pump with an electric motor, a bunker for loading the components (soybeans, wheat, peas, barley or other leguminous plants, water, supplements) and a special device to perform the mixture grinding, homogenization and thermal processing. The temperature of processing is controlled and maintained automatically.

The safe level of tripsin inhibitor (up to zero level) is guaranteed.

TEK-SM UNIT SPECIFICATIONS

| Parameter | TEK-1SM | TEK-2SM | TEK-3SM | TEK-4SM |

|---|---|---|---|---|

| Motor power, kW | 11 | 15 | 22 | 45 |

| Processing temperature, °С | 105 -110 | 105 -110 | 105 -110 | 105 -110 |

| Capacity (milk, paste), kg/h | 70/210 | 100/300 | 160/500 | 330/1000 |

| Cycle duration, min | 60 | |||

| Overall dimensions, mm | 1840 570 1650 |

2070 660 1650 |

2140 900 1700 |

2450 960 2200 |

| Weight, kg | 480 | 500 | 620 | 960 |

| Servicing staff, person | 1 | 1-2 | ||

The equipment is protected by Eurasian patents (9 countries), Canadian and USA patents on the technology and design.

2. TEK-LD LOADING DEVICE

The device is designed for:

- increasing hydrodynamic unit capacity by 30-40%;

- reducing manual labor share, thus cutting servicing staff from 2 to 1 person;

- making various feed compositions without stopping the equipment.

Dry mixture (according to the recipe) is placed into the receiving bunker, passing through the net to remove foreign objects.

A certain amount of water or another liquid (for example, skim or substandard milk) is added.

The raw stuff is soaked in the TEK-LD loading device simultaneously with feed preparation in TEK-SM unit.

On completing the boiling process in TEK-SM, another portion of raw stuff is fed to the tank by the TEK-LD pump.

SPECIFICATIONS

| Electric pump installed power, kW | 5,5-7,5 |

| Operation mode | batch |

| Feed volume, l, up to | 100-400 |

| Batch processing time, min, not more | 2 |

3. WMS PREPARATION VESSEL

The vessel is designed for making whole milk substitute by mixing the mixture from TEK-SM unit and water.

RECOMMENDED PARAMETERS:

| Parameter | TEK-1SM | TEK-2SM | TEK-3SM | TEK-4SM |

|---|---|---|---|---|

| Vessel volume, l, up to | 300 | 450 | 750 | 1500 |

| Motor power, kW | 0,55-1,5 | 1,5-2,2 | ||

| Pump capacity, m3/h | 6-10 | 10-30 | ||

← To all units

- TEK-PD cavitation-type dispersing pump

SIPE TEKMASH Institute offers dispersing pumps for making fine-dispersed food emulsions and suspensions, 10-25 m³/h capacity.

More... - Feedstock feeding equipment. Milk substitute.

The site contains information on fattening animals, on soy paste properties and soybean processing technology (animal feeding).

More... - Condensed milk line TEK-CML

Condensed milk production line

More...

- IndiaSASIL AGRO LLP

'Kshiti', 127/2, Rockel Lane,

Vakhar Bhag,

Sangli - 416416

MAHARASHTRA, India

Shreyans Shah

tel. +91-9011068877

e-mail: sasilexim@gmail.com - Colombia & LA

KAVITEC S.A.S.

Carrera 16 # 9-68

Dosquebradas, Risaralda, Colombia.?ngela Mar?a Sanz E

Gerente Comercial

email:

angela.sanz@kavitec.co

Tel?fono: 3306102

Cel: 3043289012 - Ukraine