Washing solutions and technical liquids heating system

To be considered by chief engineers and production engineers at transport and industrial plants

To be considered by chief engineers and production engineers at transport and industrial plants

Conventional technologies for heating oils, mineral oils, washing solutions and other liquids are based on preliminarily heating the working medium (water or steam) which is then fed to the heat exchanger to heat the process liquid, for example, washing solution. This two-step process evidently causes unreasonably large consumption of energy carriers because of their inevitable losses at each aggregate (heating device and heat exchanger) as well as in pipelines supplying working medium and process liquid.

TEK hydrodynamic heaters heat any liquid directly, which denies using costly heat exchangers for heating washing solutions. TEK unit efficiency is about 90% during the whole service life, thus relating direct heating technology to energy-saving ones.

Besides, being processed hydrodynamically, water (and consequently washing reagent water solution) becomes highly active, which contributes to decreasing chemical reagents concentration in the washing solution by 10-15% and to their prolonged usage.

AN ILLUSTRATIVE EXAMPLE OF USING TEK UNITS AT RAILROAD FACILITIES:

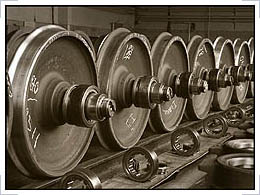

Nowadays more than 60 units are employed at rail depots (15-45 kW) for heating oils and washing solutions that contain up to 50% chemicals and organic substances (washing solutions at 95°C are used for washing roller bearings, axle-bearings and wheel pairs).

Nowadays more than 60 units are employed at rail depots (15-45 kW) for heating oils and washing solutions that contain up to 50% chemicals and organic substances (washing solutions at 95°C are used for washing roller bearings, axle-bearings and wheel pairs).

Not using steam generators and boilers is conducive to energy saving accompanied by strict observance of safety precautions and fire safety regulations. Such energy saving due to TEKMASH equipment use ensures the equipment payback within one year.

For example, at Sinelnikovo (Dnepropetrovsk railway) oil change station TEK unit (22 kW) is used for maintaining engine oil working temperature. This unit was repaid within 45 days, having replaced the boiler consuming 7 tons mazut daily and having cut the servicing staff by 9 people.

← To all units

- TEK-PD cavitation-type dispersing pump

SIPE TEKMASH Institute offers dispersing pumps for making fine-dispersed food emulsions and suspensions, 10-25 m³/h capacity.

More... - Feedstock feeding equipment. Milk substitute.

The site contains information on fattening animals, on soy paste properties and soybean processing technology (animal feeding).

More... - Condensed milk line TEK-CML

Condensed milk production line

More...

- IndiaSASIL AGRO LLP

'Kshiti', 127/2, Rockel Lane,

Vakhar Bhag,

Sangli - 416416

MAHARASHTRA, India

Shreyans Shah

tel. +91-9011068877

e-mail: sasilexim@gmail.com - Colombia & LA

KAVITEC S.A.S.

Carrera 16 # 9-68

Dosquebradas, Risaralda, Colombia.?ngela Mar?a Sanz E

Gerente Comercial

email:

angela.sanz@kavitec.co

Tel?fono: 3306102

Cel: 3043289012 - Ukraine