Food pasteurization and homogenization technology

TEKMASH company offers innovative equipment to be implemented in food industry, its operating principle and design being protected by Eurasian, USA and Canadian patents.

Today several dozens of TEK hydrodynamic units are being employed at different plants. The use of TEK units for food pasteurization, mixing, emulsification, homogenization accompanied by simultaneous hydrodynamic heating enables to do without a boiler and to perform all operations at minimum cost

Energy-saving, highly efficient technology, low operating costs are the main advantages of TEK-PH(HP) units. Cost of 1 t product pasteurization with the help of TEK-PH unit amounts to 3-8 grivnas (depending on the electricity cost).

Innovative TEK-PH (HP) hydrodynamic pasteurizers perform bulk heating of liquids, thus denying their scorching on convective surfaces inherent in conventional pasteurization technologies.

The use of TEK units for milk and milk mixes pasteurization makes them tastier due to crushing (dispergating) clots of high-molecular compounds present in milk by cavitation bubbles. The use of recuperating heat-exchanger for preliminarily heating milk at the equipment entrance contributes to cutting energy inputs. On customer's order we can make TEK units that discharge milk at the required temperature (say, ripening temperature) or deliver it to a separator.

TEKMASH offers to substitute an economical TEK unit employing our technology for the conventional one at:

- cheese manufacturing plants;

- ice-cream plants;

- condensed milk manufacturing plants;

- any food industries requiring heating, pasteurization, homogenization, emulsification, mixing, dispergation (choice of equipment and necessary calculations are performed by TEKMASH free of charge).

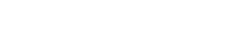

Possible applications of TEKMASH technology

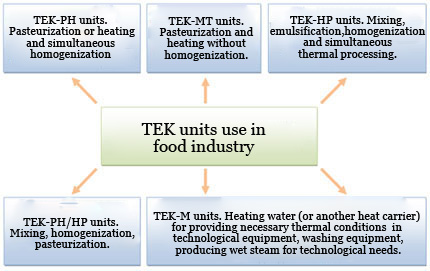

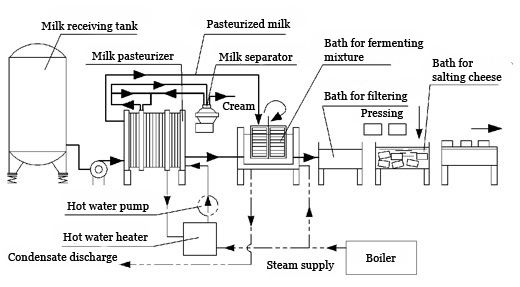

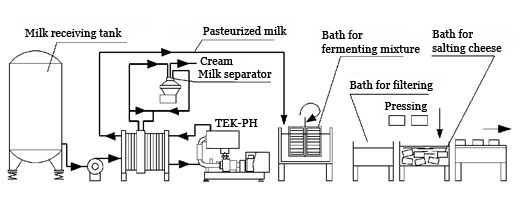

Cheese manufacturing plant layout

capacity - 20 t milk per shift)

Conventional layout

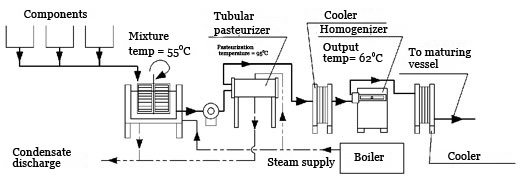

TEKMASH technology - 1

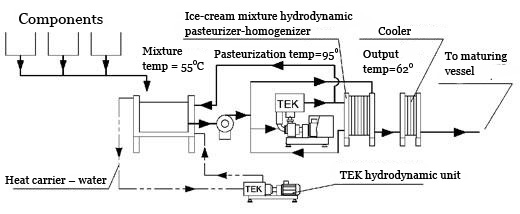

TEKMASH technology - 2

Total TEKMASH equipment power is 90 kW.

TEKMASH equipment advantages lie in:

- not using a boiler (not buying costly steam) in spring and autumn months;

- cutting energy inputs by 40-60%;

- potential for getting several tons of hot water and several hundreds of kilograms of wet steam (up to 115C) daily;

- potential for heating premises during the transitional period (March-April, October-November).

TEKMASH authority

- survey of the facility and decision making;

- manufacturing equipment;

- equipment delivery and installation;

- reconfiguration of heat exchangers;

- equipment adjustment, commissioning and tests;

- staff training;

- warranty service (1 year).

Ice-cream manufacturing plant

conventional layout

TEKMASH technology

TEKMASH technology advantages lie in:

- practical ice-cream cost reduction by 10-20% due to performing three operations in one unit;

- 2-3-fold energy consumption reduction;

- denial of costly steam;

- 1.5-2-fold process intensification;

- efficient introduction of additives and fillers into mixture;

- ice-cream high quality.

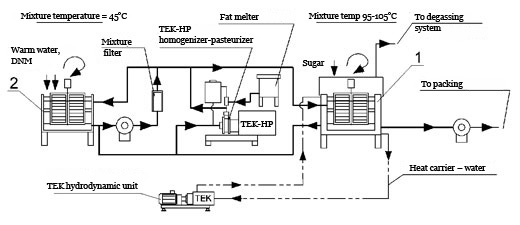

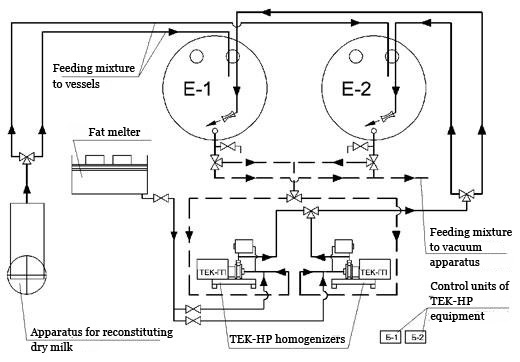

Dry components condensed (caramelized) milk production scheme

TEK-HP unit is designed for making condensed (including caramelized, boiled) milk with sugar, its raw stuff being dry non-fat milk (DNM), dry whole milk (DWM), dry whey, sugar, vegetable oil, butterfat, flavor additives.

Production process consists of the following stages:

- filling vessel 1 with operating fluid (water, whey, milk, etc.);

- heating the liquid to dissolve dry components by means of the vessel thermal jacket, heat carrier being prepared by TEK unit;

- pumping vessel 1 contents to vessel 2;

- starting TEK-HP hydrodynamic homogenizer-pasteurizer to ensure circulation along "vessel 2 - TEK-HP - vessel 2" closed circuit;

- introducing DNM (DWM) into vessel 2 while circulating the operating liquid, mixing and heating the mixture to the temperature at which vegetable oil is introduced;

- introducing preliminarily melted vegetable oil into TEK-HP hydrodynamic unit and circulating the mixture until the oil is fully emulsified;

- pumping the mixture to vessel 1;

- circulation along "vessel 1 - TEK-HP - vessel 1" closed circuit;

- introducing sugar into vessel 1 while circulation goes on;

- heating the mixture to pasteurization temperature (for condensed milk) or to caramelization temperature (for caramelized milk) while circulation goes on;

- holding the mixture (for caramelized milk) and simultaneously circulating it;

- cooling and packing.

Cooling the mixture to packing temperature can be done either in a vacuum-crystallizer or by supplying refrigerating medium to vessel 1 heat jacket.

TEKMASH equipment application for manufacturing condensed (caramelized) milk is advantageous for the following reasons:

- high quality condensed milk can be made from various raw stuff containing cheap components, without using vacuum apparatus or steam;

- manufactured condensed (caramelized) milk can be used both in confectionary industry and directly in various packages: polyethylene packs, cans, cardboard boxes, various polymeric containers as well as in conventional glass or tin containers, which contributes to high demand and at the same time reduces product cost;

- manufacturing milk does not depend on gas supply (boiler) and can continue at big milk plants when the boiler is stopped;

- milk production becomes much easier and considerably less expensive.

СPreparation of mixture for manufacturing combined (with vegetable oil) condensed milk using conventional technology and vacuum evaporator.

TEK-HP equipment use for making mixtures "milk basis - vegetable oil" helps:

- to improve quality and consistence of canned combined milk;

- to deny demixing during shelf-life;

- not to perform homogenization before packing .

TEK-HP hydrodynamic units are easy to operate. They are intended for cleaning-in-place. As there are no heating surfaces the unit denies milk stone formation, scorching, etc. which is beneficial for product quality and, consequently, promotes demand.

Wasteless technology makes the equipment ecologically friendly. Our specialists can perform equipment installation, matching it to the existent technological line, commissioning and starting up, servicing staff training, warranty and post-warranty service.

TEKMASH authority:

- power calculation and manufacturing equipment in the shortest time;

- equipment installation and adjustment;

- matching our equipment to the customer's basic equipment;

- training servicing staff;

- 12 month warranty service.

- TEK-PD cavitation-type dispersing pump

SIPE TEKMASH Institute offers dispersing pumps for making fine-dispersed food emulsions and suspensions, 10-25 m³/h capacity.

More... - Feedstock feeding equipment. Milk substitute.

The site contains information on fattening animals, on soy paste properties and soybean processing technology (animal feeding).

More... - Condensed milk line TEK-CML

Condensed milk production line

More...

- IndiaSASIL AGRO LLP

'Kshiti', 127/2, Rockel Lane,

Vakhar Bhag,

Sangli - 416416

MAHARASHTRA, India

Shreyans Shah

tel. +91-9011068877

e-mail: sasilexim@gmail.com - Colombia & LA

KAVITEC S.A.S.

Carrera 16 # 9-68

Dosquebradas, Risaralda, Colombia.?ngela Mar?a Sanz E

Gerente Comercial

email:

angela.sanz@kavitec.co

Tel?fono: 3306102

Cel: 3043289012 - Ukraine