Hydrodynamic heating as a substitute for ultrapasteurization (UHT)

(Nature cannot be fooled!)

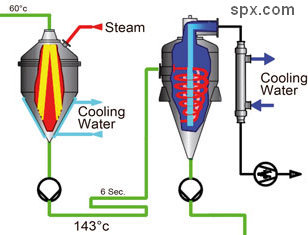

Recently ultrapasteurization equipment has become increasingly popular in dairy industry. Direct steam ejection into the moving stream of food liquid causes temperature abrupt increase to 110-140°C. Microorganisms are destroyed almost immediately. After that the superheated liquid mass gets into a specially shaped chamber (Laval nozzle) where it instantly expands and cools down.

The processes of heating, sterilization and cooling occur instantaneously, taking 1 – 3 seconds and yield ultrapasteurized milk with a long shelf-life (6 months or more).

Along with the undisputable advantages the UHT-technology has certain disadvantages:

Special mention should be on the ultrapasteurized milk quality. Its organoleptic properties are characterized by the lack of natural fresh milk taste and flavor. Thus, 10% single-dose cream after ultrapasteurization tastes rather like 1% milk, even not 3.6% milk!

Certain taste “emptiness” is due to the destruction of some rennet proteins, including sulfur-containing ones, as well as thermally unstable methionine and tryptophan which takes place at super-high temperatures. Instant micro explosion and steam bubbles condensation are harmful not only for bacteria and spores but for essential amino acids extended chains.

Similar though less pronounced effect characterizes conventional milk pasteurizers and sterilizers with convective heating surfaces. For example, plate sterilizers are affected by accumulating deposits on the heat-exchanger hot surfaces. Some milk burning, loss of calcium salts and group B vitamins (especially B2) affect substantially the finished product quality making it poorly digestible because of lack of vitamins.

These disadvantages caused by milk overheating can be avoided if use is made of milk pasteurizers (sterilizers) applying hydrodynamic volume heating produced by cavitation and turbulent friction.

The absence of convective heating surfaces as well as bacteria destruction by hydraulic shock which happens when cavitational bubbles collapse, make it possible to lower the thermal processing temperature necessary for achieving the required sterility.

As directed by the milk processing plant production engineer, the thermal processing temperature can be finely adjusted within the range of +60°C - 132°C. It should be underlined that the required temperature can be maintained indefinitely, the accuracy being ±0.2°С

By using some know-how the temperature accuracy is maintained without any automatic systems, which reduces substantially the equipment cost and facilitates its commissioning.

Milk with long shelf-life made by using HTD-technologyTM is characterized by high organoleptic quality. The technology makes it possible to combine liquid heating and emulsification, thus being indispensible in producing yoghurts, kefirs, ice-cream mixes, etc.

You can read more about milk pasteurizers here.

- TEK-PD cavitation-type dispersing pump

SIPE TEKMASH Institute offers dispersing pumps for making fine-dispersed food emulsions and suspensions, 10-25 m³/h capacity.

More... - Feedstock feeding equipment. Milk substitute.

The site contains information on fattening animals, on soy paste properties and soybean processing technology (animal feeding).

More... - Condensed milk line TEK-CML

Condensed milk production line

More...

- IndiaSASIL AGRO LLP

'Kshiti', 127/2, Rockel Lane,

Vakhar Bhag,

Sangli - 416416

MAHARASHTRA, India

Shreyans Shah

tel. +91-9011068877

e-mail: sasilexim@gmail.com - Colombia & LA

KAVITEC S.A.S.

Carrera 16 # 9-68

Dosquebradas, Risaralda, Colombia.?ngela Mar?a Sanz E

Gerente Comercial

email:

angela.sanz@kavitec.co

Tel?fono: 3306102

Cel: 3043289012 - Ukraine